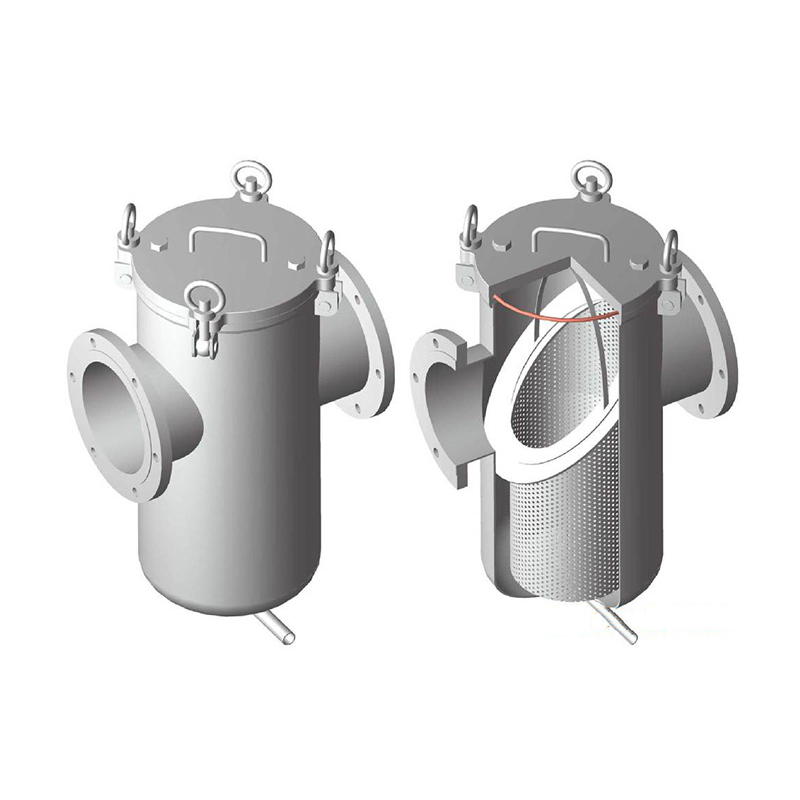

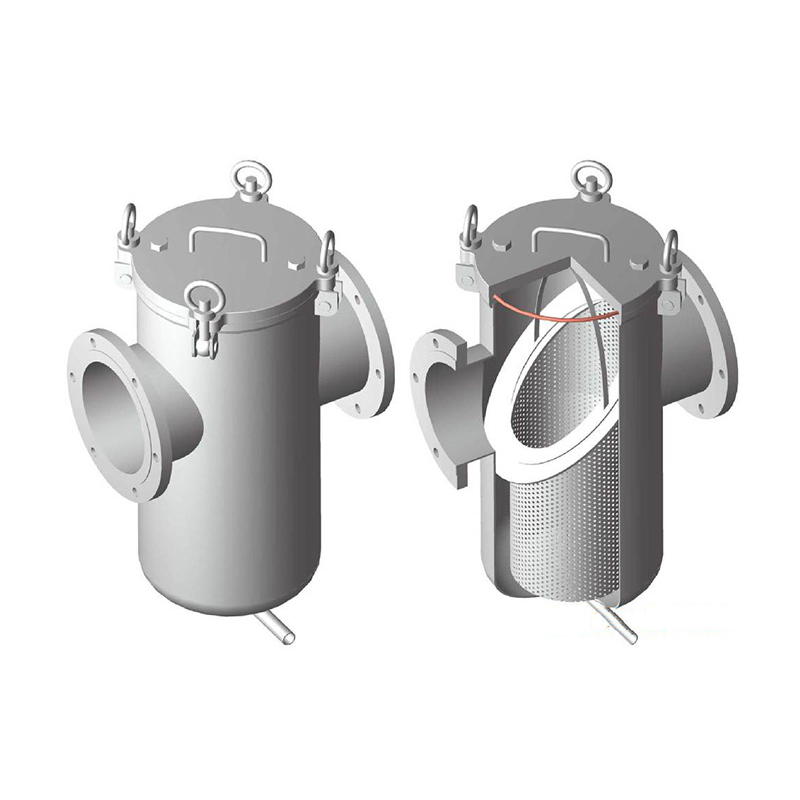

Basket filter is composed of connecting pipe, main pipe, flange, flange cover,

filter basket screen and fasteners. When the fluid enters the filter cartridge equipped with a filter screen of a certain specification, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is needed, open the drain valve, drain the remaining liquid, remove the upper cover, take out the filter basket, clean it, then reinstall it.

Basket filter is an indispensable device on the pipeline of conveying medium. It is usually installed at the inlet of pressure reducing valve, pressure relief valve, fixed water level valve or other equipment to filter impurities in the medium to protect the valve and equipment. Basket filter is widely used in the industries of chemical, petrochemical, petroleum, paper, mining, electric power, liquefied gas, food, pharmaceuticals, water supply and drainage, municipal project, mechanical equipment, electronics, construction and other fields.

How to install?

1. Before installation, please make sure the fastening of the screws and the filter is clean. The basket filter is generally installed horizontally. The direction of the inlet and outlet should be consistent with the direction of the arrow on the valve body. Install before the pipe inlet ( Before the pump). During installing, please pay attention to the sign of flow direction.

2. The core part of filtering is the cylindrical screen. The screen is made of wire mesh or wedge wire. The screen is wearing part and it needs to be regular maintained.

3. After working for a period of time, certain impurities can be precipitated in the filter basket. Pressure drop will increase and the flow rate will decrease consequently. Therefore, the impurities in the filter basket must be removed in time.

4.

Filter basket shall be protected from deformation or damage when cleaning impurities, otherwise poor performance of filtering will occur.