Self-cleaning filters are used to protect pipelines and various downstream equipment. Without adequate filtration, the scale will build up in the channel and increase the energy required to pump the water.

Scraper Cleaning Type self-cleaning filter automatically removes particles and impurities from the inner surface of the screen through the scraper inside of the screen drum, while keeping the filtration process uninterrupted. Our self-cleaning filter solves the filtration problems you may encounter in production with excellent filtration performance.

1. Fully automatic operation with 24-hour uninterrupted online filtration.

2. Automatic discharge of waste liquid containing high concentrations of impurities, which can be recycled to reduce the loss of high-value materials.

3. Airtight filtration, eliminating the leakage of harmful substances, ensuring work safety and employee health.

4. Adopting metal plate scraper, with a small gap between scraper and drum screen. Accurate slot, extremely smooth surface, easy to clean and avoid crushing impurities

5. The backwashing function can be added to help clean the drum screen.

In addition to the showed filter range, we can also manufacture Custom Made with deviating specifications at the customer’s request.

For the right filtration solution and filter products, contact or email [email protected] filter specialist.

We are happy to help you.

Our team of filter specialists is are 24/7 available.

We are in liquid filtration for over 15 years.

| Liquid Viscosity | Liquid of ordinary viscosity |

| Filter rating | 30-1500μm |

| Design pressure | 1.0MPa or customized |

| Design temp. | 0-200℃ |

| Filtering area | 0.14m²-1.45m² |

| Press difference | 0.05MPa |

| Pressure alert | Pressure switch |

| Gearmotor | 550W,three-phase,380V,IP55 |

| Inlet/outlet flange | HG20592-2009, HG20615-2009(ANSI B16.5) |

| Drum screen | Wedge wire,SS304/SS316L/2205/Titanium |

| Housing material | 304/316L/CS |

| Scraper material | Copper/alloy steel/PTFE |

| Seal material | NBR/VITON(FKM) |

| Drain valve | Electric/pneumatic ball valve,IP55 |

| 380V AC,0.4-0.6MPa clean and dry compressed air |

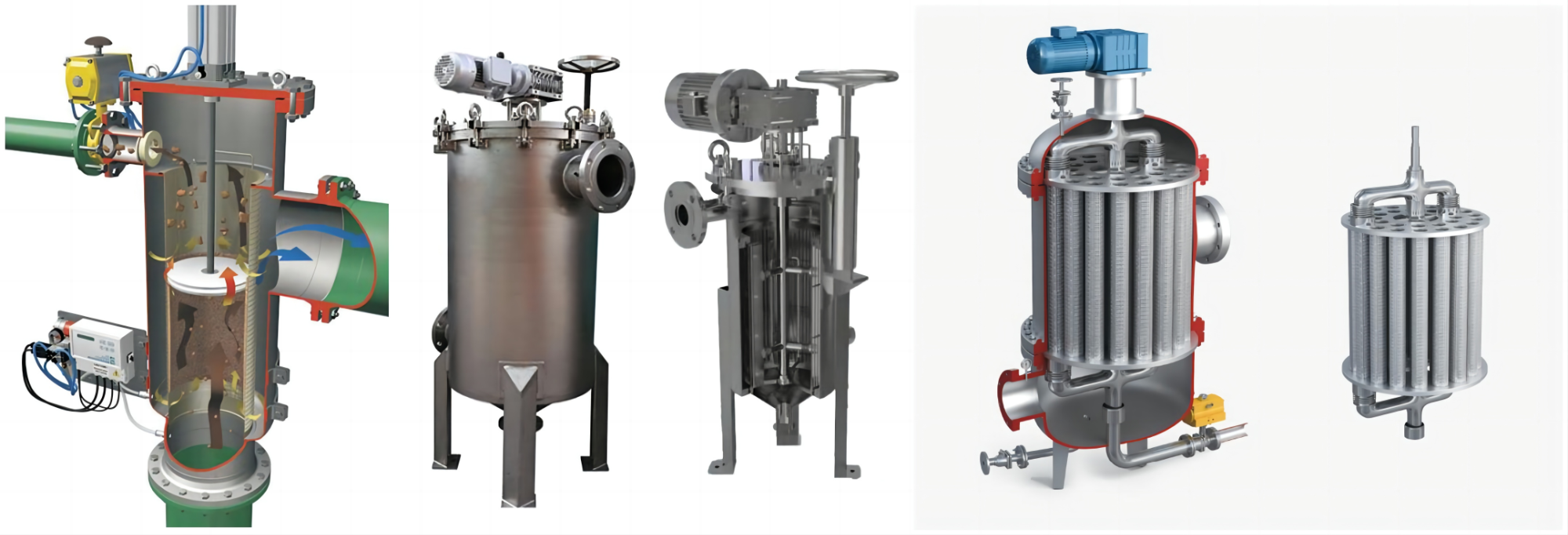

Scraper self cleaning filters: Cleaning by the rotary scraper.

Disc self cleaning filters: Cleaning by vertical up and down.

Backwash Self-cleaning Filter Housing: Automatic continuous on-line filtration without downtime for cleaning