The wedge wire screen technology is highly favored in manufacturing paints, resins, inks, dyes, pharmaceuticals, chemicals, and petrochemicals.

Wedge wire screens play a vital role in improving operational efficiency and reliability at all stages of petrochemical production.

Various Wedge Wire Screens for Petrochemical Industries

Our support grids are designed to provide structural support for the catalyst bed within the reactor. It promotes uniform flow distribution of reactants through the catalyst bed and maximizes the efficiency of chemical reactions.

The wedge wire tubes are the key component of reactor internals. It possesses high compressive strength, flatness, and verticality, playing a crucial role in producing raw materials for the catalytic reforming of petrochemicals.

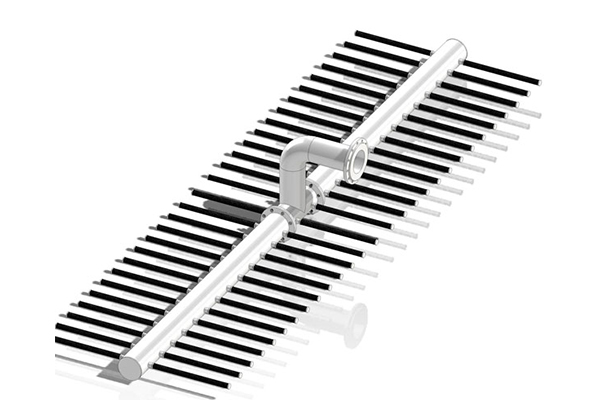

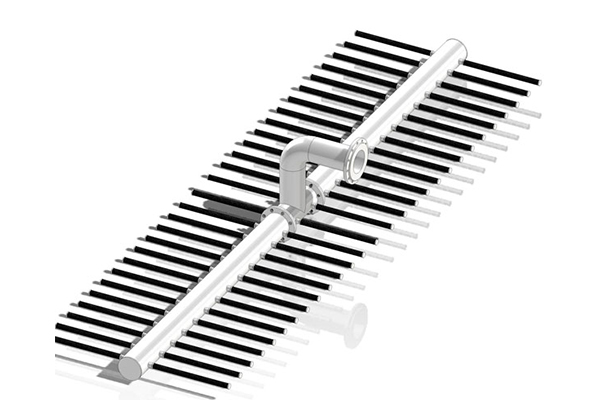

The wedge wire scallops are installed in the reforming reactor and have a fan-shaped cross-section, hence its name. Designed to retain catalyst in radial flow device and prevent catalyst leakage.

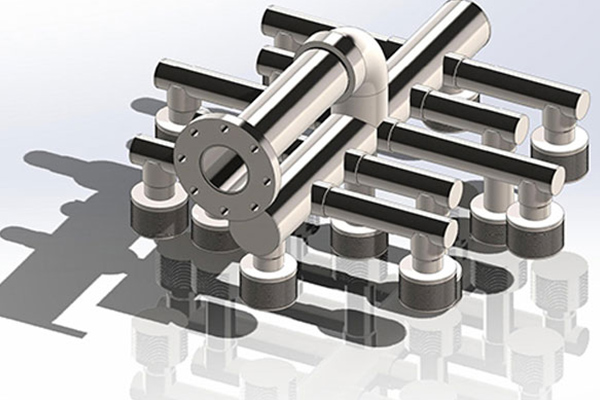

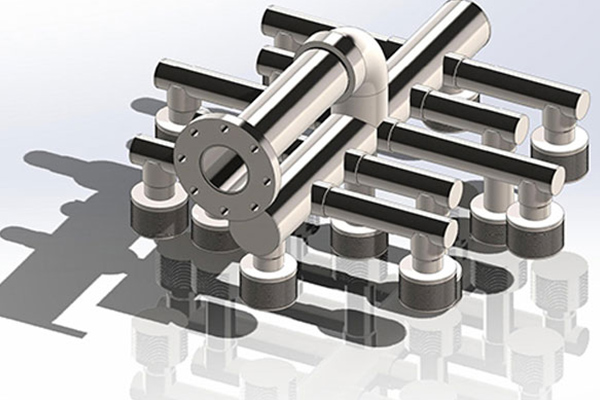

Our wedge wire header lateral screen can be custom-designed for various types and specifications to meet your petrochemical requirements. It can effectively collect or distribute liquid/gas while preventing the media from flowing out.

The filter nozzles are widely used in various chemical and petrochemical processes to uniform fluid or gas distribution. It is simpler, more flexible, and can also be used with distributors

Our wedge wire resin trap is a device used to capture resin particles carried out of the ion exchanger with water. It ensures no complete loss of media in the event of a failure.

We can provide the above various wedge wire screens for petrochemical applications. We also offer various wedge wire screen OEM services.

Wedge wire screen has excellent filtration capacity and structural integrity. Apart from the petrochemical industry, it can also find applications in water treatment, mineral mining, natural gas filtration, and various other industries. If you have any requirements, please feel free to contact us!

CONTACT US