Titanium powder sintered filter (including tube and plate) is a kind of new high-efficiency porous filter material made by industrial high purity titanium powder (99.4%) as raw material, through powder grading, molding, sintering, mechanical welding, and other process. It is widely used in the pharmaceutical industry, water treatment industry, food industry, bioengineering, chemical industry, petrochemical industry, metallurgical industry, and gas purification field. Because of its pore and filtration precision, it can be adjusted in a wide range. Titanium powder sintered filter plate or tube is a new filter material that has a broad development prospect.

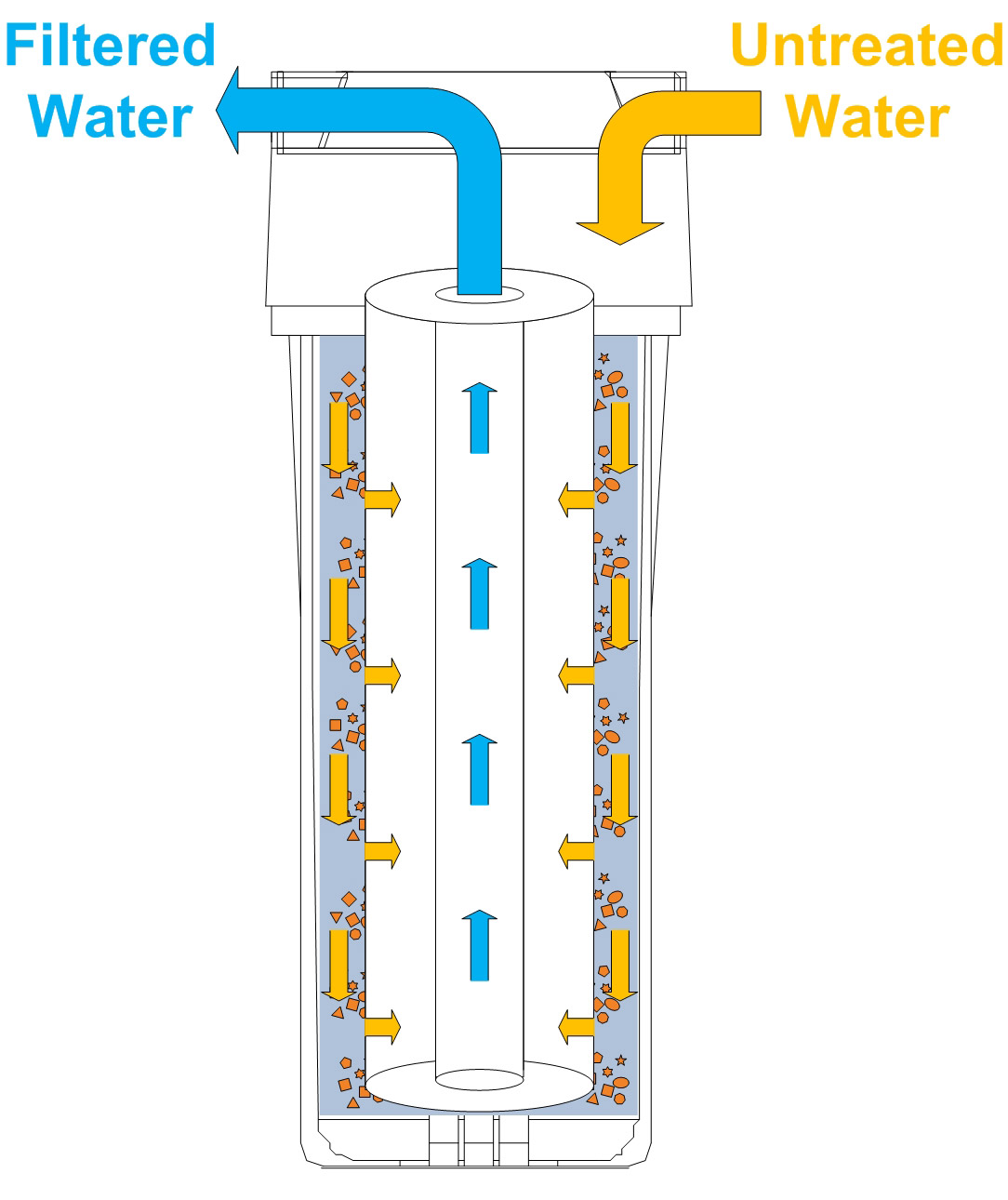

Sintered powder filter can realize micro-scale precision filtration, which can separate solid particles in liquid and gas. When the fluid passes through a certain precision filter element, the impurities are blocked on the surface of the filter to form a filter cake, and the pure fluid flows out through the filter element. The contaminated or contaminated fluid is cleaned to the state required for normal production to ensure that the downstream unit obtains a clean product or protects the equipment from normal operation.

Advantage:

1. Strength: High mechanical strength and compressive strength.

2. Easy to clean: As a result of the surface of the filter material, having means for cleaning characteristics, especially suitable for backwashing.

3. Easy processing: suitable for cutting, bending, stamping, drawing, welding, and other processes.

4. High temperature: 480 °Ccan withstand high temperatures.

5. Corrosion resistance: As a result of SUS316L, 304 materials, the corrosion resistance.

6. Filtration: Filtration range of 1μm-200μm, has a reliable filter performance.

7. Stability: Because there are two layers to do to protect the screen, plus solid melting diffusion sintering process which makes filters is not easy to deform.

Specifications:

|

Filtering |

Filtration |

Maximum |

Permeability |

Permeability |

Thickness |

Compression |

Bubbling |

|

S9 |

0.2 |

2.5 |

|

1 |

0.6~10 |

3.0 |

|

|

S8 |

0.5 |

4 |

|

3 |

0.6~10 |

3.0 |

|

|

S7 |

1.5 |

6 |

|

5 |

0.6~10 |

3.0 |

|

|

S6 |

2.5 |

10 |

0.09 |

10 |

0.6~10 |

3.0 |

9.16 |

|

S5 |

5 |

15 |

0.23 |

40 |

0.6~10 |

3.0 |

6.1 |

|

8 |

20 |

0.91 |

80 |

0.6~10 |

3.0 |

4.6 |

|

|

S4 |

10 |

30 |

1.81 |

160 |

0.6~10 |

3.0 |

2.6 |

|

S3 |

28 |

60 |

3.82 |

350 |

0.6~10 |

3.0 |

1.8 |

|

35 |

80 |

7.29 |

500 |

0.6~10 |

3.0 |

1.4 |

|

|

S2 |

40 |

100 |

9.43 |

700 |

0.6~10 |

3.0 |

1.1 |

|

S1 |

65 |

160 |

15.1 |

1000 |

0.6~10 |

3.0 |

0.66 |

Application:

1: catalyst filtration;

2: filtering liquids and gases;

3: mother liquor recovery filtration in PTA production;

4: filtration in food and beverage;

5: boiling vaporized bed;

6: liquid flushing bubbles;

7: fire retardant;

8: Balanced, damped airflow;

9: probe protection of the sensor;

10: Filtration and noise reduction on pneumatic equipment;

11: fly ash treatment;

12: Gas homogenization and pneumatic conveying in the powder industry.

13. Steam filtration.

14. Filtration stage after ozone sterilization and filtration of ozone aeration.

15. Filtration in decarbonization and dilution of transfusion.

16. High corrosive liquid and gas purification.

17. High pressure and temperature resistance.

18. Oil sands separation in the oilfield.

Packaging: