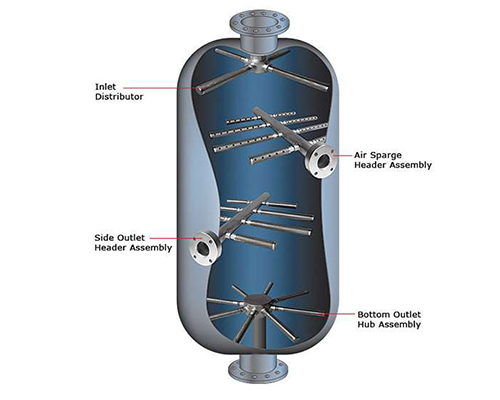

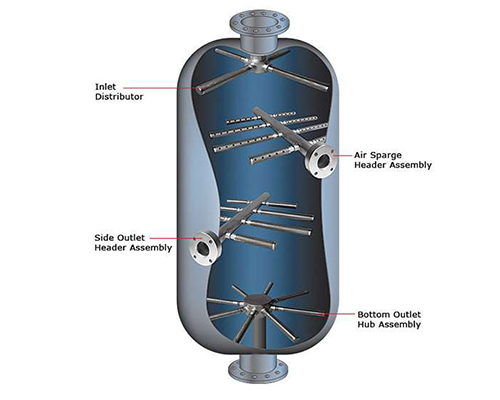

The incorporation of Header Lateral Screens within vessel internals provides a means to manage fluid flow, separation, and filtration processes. These header laterals contribute to streamlined operations, reduced maintenance, and improved overall efficiency.

Vessel internals, integral components of industrial vessels such as reactors, distillation columns, and separators, play a crucial role in facilitating complex processes like filtration, separation, and fluid distribution. The introduction of Header Lateral Screens marks a significant departure from conventional methods of internal component design.

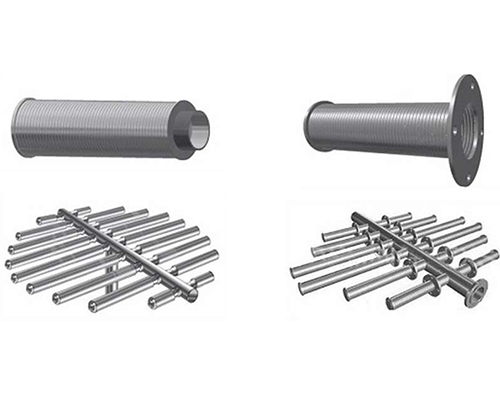

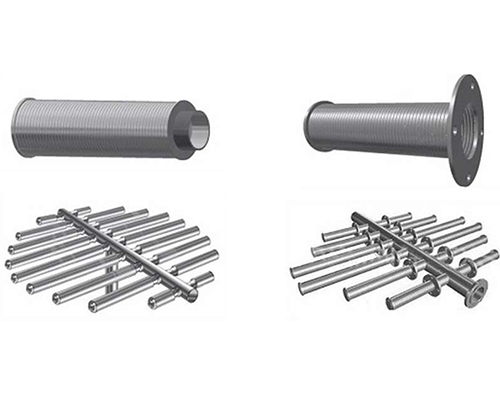

Traditionally, vessel internals were characterized by their intricate network of pipes, tubes, and baffles, aimed at optimizing processes within the vessel. However, Header Lateral Screens introduces a more streamlined and efficient approach. These screens are designed as horizontal panels positioned inside the vessel, featuring strategically placed perforations or openings. Their primary purpose is to facilitate controlled fluid distribution, collection, and separation.

Wedge Wire Header Lateral Screens Custom Design

YUBO Filtration is a professional manufacturer of wedge wire screens in China. Our wedge wire header lateral screens are of high quality and cost-effective!

Quickly Inquiry

Benefits of Header Lateral Screens in Vessel Internals

▪ Enhanced Fluid Distribution: The strategic arrangement of perforations in Header Lateral Screens ensures uniform fluid distribution, minimizing the risk of uneven flow patterns that can negatively impact process efficiency.

▪ Optimized Filtration and Separation: In applications that involve filtration and separation, Header Laterals aid in achieving precise separation between different components of a mixture. The screens act as barriers that allow selective passage of substances, leading to more accurate and efficient separation processes.

▪ Reduced Fouling and Clogging: The design of the screens discourages the accumulation of debris and particulates that could lead to fouling or clogging. This results in extended operational intervals and reduced maintenance requirements.

▪ Customization and Flexibility: Engineers and designers can tailor the design of Header Lateral Screens to meet the specific requirements of different processes. This adaptability allows for a more targeted and efficient approach to fluid handling.

▪ Improved Flow Dynamics: The use of Header Lateral Screens can help mitigate issues related to turbulence and backflow, thereby promoting smoother fluid flow and better process control.