When considering the recommended degree of angle for the DSM screen, it is essential to first understand what DSM screens are.

What is the DSM screen?

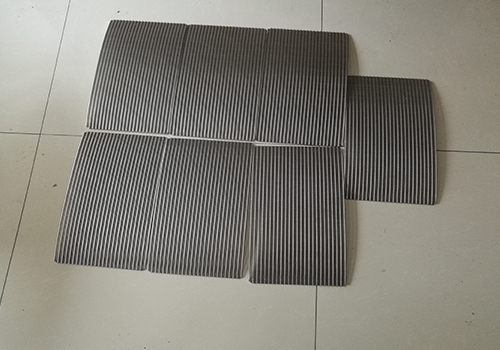

Wedge wire DSM screens, also known as sieve bend screens or dewatering screens, are a type of filtration screen used in various industries for solid-liquid separation processes. They are particularly effective in applications where fine particles need to be separated from liquids, such as in mining, food processing, water treatment, and industrial processes.

The term wedge wire refers to the shape of the filtering surface of these screens. Instead of traditional woven mesh or perforated plate screens, wedge wire DSM screens are made of stainless steel profile wires that are shaped like narrow triangles (wedges) and are welded together to form a curved screen surface. The wedge-shaped wires have precise and consistent gaps between them, creating a series of narrow openings along the curved surface.

How much degree of angle is recommended for the DSM screen?

DSM screens(sieve bend screens) can be customized with various radii and angles to suit specific requirements. Commonly employed angles include 45°, 60°, 90°, 180°, and 270°.

In gravity flow DSM screens, the arc angles of 45°, 60°, and 90° find frequent use and are typically implemented in coal preparation plants and concentrators. On the other hand, pressure-type DSM screens often utilize 180° and 270° radian angles for grading operations in the cement industry's grinding process.

By the way, we can design various sizes and angles of stainless steel wedge wire DSM screens for industrial filtration.

Contact Us

WhatsApp: 86 13653285589

Furthermore, the advantages of customizing the DSM screen are also evident.

1. Filtration Efficiency: The wedge-shaped wires and precise gaps allow for the efficient separation of fine particles from liquids while minimizing the risk of clogging.

2. Dewatering Capability: These curved screens are effective in dewatering processes, helping to remove excess moisture from solids.

3. Sturdy Construction: Wedge wire DSM screens are made from durable stainless steel, making them resistant to corrosion and wear, and suitable for demanding industrial environments.

4. Customizable Design: The slot size between the wedge wires can be tailored to specific application requirements, enabling fine-tuning of the filtration process.

5. Self-cleaning Effect: The curved design and narrow slots create a self-cleaning effect as the liquid passes through, preventing the buildup of debris and reducing maintenance needs.

Conclusion

The unique design and robust construction make DSM Screens ideal for applications where precision, durability, and self-cleaning capabilities are required.