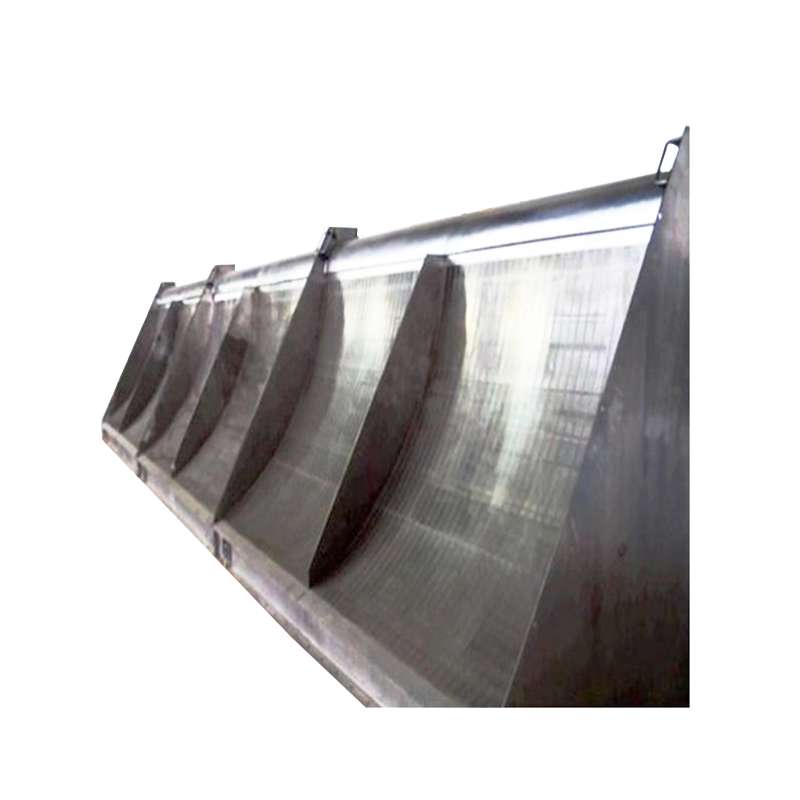

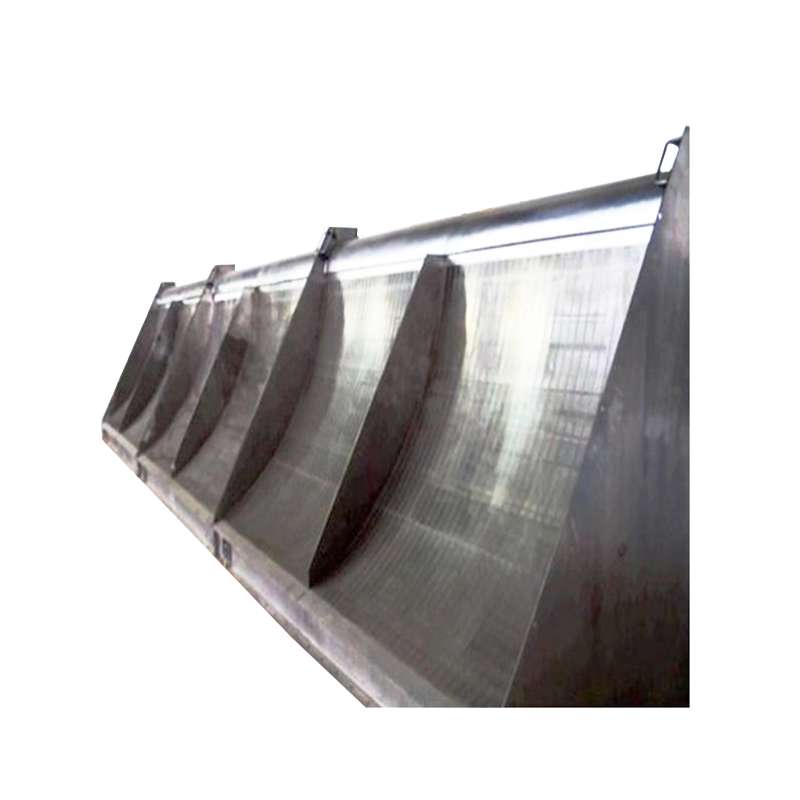

Sieve bend is one type wedge wire screen, often seen in applications: Breweries, Fish processing, Fruit juice processes, Mineral processing, pulp & paper mills and sugar mills.

SIEVE BENDS IN A RANGE OF SIZES AND PROFILES TO SUIT APPLICATIONS:

Materials: Stainless Steel 304 or 316, polyurethane screen, low carbon steel.

Wire Diameter: from 0.35mm and 5mm.

Hydraulic or pneumatic tilting for swivel mechanism in sieve bend housing.

When we choose the sieve bend for application, please take attention to them:

strong>Particle size cut point.

Feed rate.

Solids concentration.

Maximum particle size or size distribution.

HERE IS THE SIEVE BEND WORKING PROCESSING IN SOLID/LIQUID SEPARATION:

Solids-bearing liquid (or slurry) is poured into the feed box and overflows onto the screen. The sharp, leading edge of each wedge wire slices away a thin layer of water and small-particle solids. Larger particles continue down the screen surface until most of the liquid is removed. The size of particles separated is determined by the size of the coal particles and their settling velocity in the liquid.

Now with an inquiry info of sieve bend, have a further learing about sieve bend screen products.