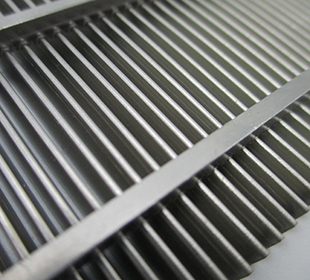

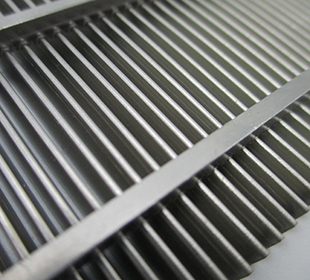

The application of

wedge wire mineral screen is more and more widely in industrial and mining enterprises, but it is still a headache for enterprises to choose wedge wire mineral screen. In fact, we only need to pay attention to this aspect to solve the problem: first of all, the wedge wire mineral screen is to select materials. See whether the mesh size of the wedge wire mineral screen is uniform, authentic, and the mesh size of the large manufacturers is uniform. See if the wire rope is in the center of the skeleton.

Looking at the opening rate of the

wedge wire mineral screen, the more the number of openings, the higher the opening rate, the higher the screening power and output value. The service life of the screen is long and the bearing capacity is large. It has high tensile strength and can bear more than 2.5 times the rubber screen. Its service life is 8-10 times longer than that of general metal screen, 3 times of stainless steel screen surface, 3.9 times of natural rubber screen surface, and now it is the screen surface with wear resistance in the world.

The production data of the wedge wire mineral screen is polymer organic elastomer, which has excellent wear resistance, flexing resistance and large bearing capacity. The material of the screen mesh has been specially treated, and it will never be delaminated under the long-term load-bearing effect. The processing method of screen barrel: in this link, CNC punch is generally used for punching. During punching, the manufacturer shall pay attention to the hole size to prevent the standards required by customers. What kind of standard customers need should be cut according to a certain proportion. In the process of cutting, we must pay attention to the correct use of equipment. Once this happens to the product, the user is unacceptable. If in the manufacturing process, the punching mesh product exceeds the length range advised by the customer, then the technical personnel should remove the remaining length or corner to ensure the normal use of the user.

The

wedge wire mineral screen is easy to leak, wear-resistant and corrosion-resistant. Widely used in screening, filtration, dehydration, desliming, and other industries, used in mining, coal, kerosene, fertilizer, grain, salt, environmental protection, and other industries.