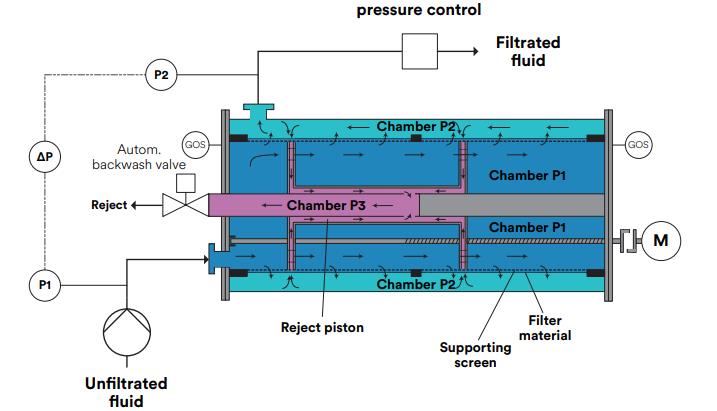

Auto Self Cleaning Filter is a self-cleaning suction scanning filter equipped with a motorized adaptive suction pad cleaning system that easily regenerates the filtering element within a few seconds, without interrupting the flow. This filter is ideal to treat water loaded with suspended solids and can be implemented in various industrial applications: process water treatment, closed circuit systems, fire prevention systems, and many more.

Self-Cleaning Suction Intake Filters & Strainers are for use with surface-mounted pumps. They are a welcome alternative to the traditional suction intake basket strainer. All our filters are self-cleaning automatic backwash filters – the self-cleaning mechanism prevents the filter from blinding or the pump from blocking.

Product Advantage

1. The Self-Cleaning Suction Intake Filters adopts a stainless steel wedge wire filter element structure, which can maximize the effective filtering area;

2. High-efficiency backwash technology, combined with laser welding technology, the filter is suitable for the sea and ships.

3. In addition to satisfying the flow rate of normal design, a set of spare filter elements is added. When cleaning is required, the spare filter element is started, so it will not affect the pipe resistance.

4. The cleaning assembly is in the form of sucking up and down, which maximizes the cleaning of impurities in the shortest time.

5. Clean the gasket at the rotating shaft and filter element faceplate, and have an automatic adjustment function according to the wear, so as to minimize the side leakage.

Product application industries:

● Water/wastewater treatment

● Pulp and Paper

● Chemicals

● Petrochemicals

● Steel

● Nonferrous metal

● Plastic extrusion

● Machine coolant filtration

● Construction sector

In addition to the showed filter range, we can also manufacture Custom Made with deviating specifications at the customer’s request.

For the right filtration solution and filter products, contact or email [email protected] filter specialist.

We are happy to help you.

Our team of filter specialists is are 24/7 available.

We are in liquid filtration for over 15 years.

|